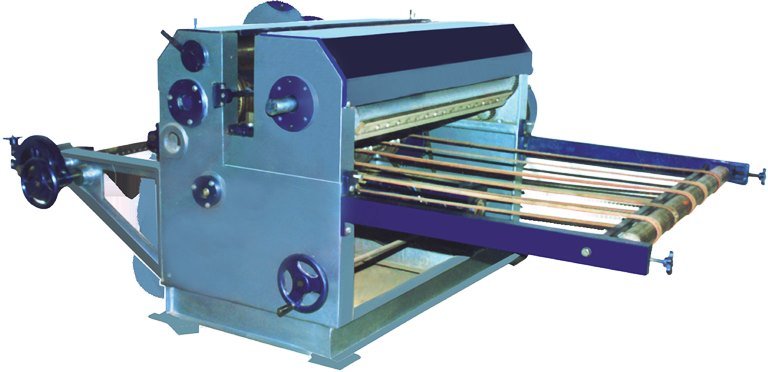

Rotary Sheet Cutter

Products

Rotary Sheet Cutter

A rotary sheet cutter is a mechanical device used for cutting sheets of various materials, such as paper, cardboard, plastic, and metal, into smaller pieces or specific shapes. These machines are commonly used in industries like printing, packaging, and manufacturing, where precise and efficient sheet cutting is required. Here are some key features and information about rotary sheet cutters:

Rotary Cutting Mechanism: Rotary sheet cutters employ a rotating cutting blade or wheel to cut through the sheet material. This mechanism offers precise and clean cuts, making it suitable for various applications.

Sheet Feed System: Rotary sheet cutters typically include a system for feeding sheets of material into the cutting area. This ensures that the material is accurately positioned for cutting.

Adjustable Cutting Width: Many rotary sheet cutters allow you to adjust the cutting width, making it possible to cut sheets into different sizes and shapes as needed.

Cutting Speed: These machines come with variable cutting speeds, which can be adjusted to match the requirements of the specific material being cut and the desired level of precision.

Material Compatibility: Rotary sheet cutters are versatile and can handle a wide range of materials, including paper, cardboard, plastic, foil, fabric, and more. They are particularly useful for tasks that require intricate or curved cuts.

Safety Features: Modern rotary sheet cutters often come equipped with safety features, such as guards to prevent accidental contact with the cutting blade.

Automation: Some rotary sheet cutters can be integrated into automated production lines, where they can be programmed to cut sheets in a precise and consistent manner.

Scalability: These machines come in various sizes and configurations to accommodate different workloads and sheet sizes. You can find small, tabletop versions for light-duty tasks and large, industrial-sized cutters for heavy-duty operations.

Maintenance: Regular maintenance is essential to keep a rotary sheet cutter in optimal working condition. This typically involves blade sharpening or replacement and lubrication of moving parts.

Applications: Rotary sheet cutters are used in a wide range of industries, including printing and publishing, packaging, labeling, textile manufacturing, and even in the production of items like labels, stickers, business cards, and packaging materials.

Customization: Some rotary sheet cutters can be customized to meet specific requirements, such as cutting patterns or shapes for specialized products.

Cost: The cost of rotary sheet cutters varies depending on their size, features, and capabilities. Smaller, manual models are more affordable, while larger, automated industrial machines can be quite expensive.