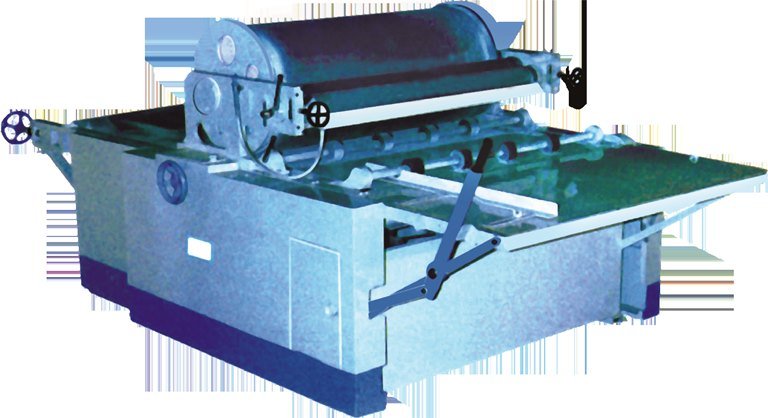

FP-100 Flexo Printer

Products

FP-100 Flexo Printer

Flexo printing is a versatile printing technology commonly used for a wide range of applications, including packaging, labels, newspapers, and more. Flexo printers have the following features:

Plate-Based Printing: Flexo printing uses flexible relief plates made from materials like rubber or photopolymer. These plates are mounted on cylinders and transfer ink to the printing substrate.

Versatility: Flexo printers are used for printing on various substrates, including paper, cardboard, plastic, film, foil, and even fabric. This versatility makes them a popular choice for packaging materials and labels.

Fast Printing Speeds: Flexo printing is known for its high-speed capabilities, which make it suitable for large production runs.

Multiple Color Printing: Flexo printers can use multiple ink stations, allowing for multi-color printing in a single pass.

In-Line Processing: Many flexo printers are equipped with in-line finishing and converting options, such as die-cutting, laminating, and slitting, which can significantly reduce post-printing processing time.

Precision Registration: Flexo printers offer accurate registration of colors and images, ensuring that the final printed product looks sharp and well-aligned.

Water-Based and UV Inks: Flexo printers can use a variety of inks, including water-based and UV inks, depending on the specific requirements of the job.

Low Waste: They generate relatively low levels of waste due to their ability to print directly on the substrate.

Customization: Flexo printers can be customized to meet the needs of different industries and applications, from food packaging to labels and newspapers.

Cost-Efficiency: Flexographic printing can be cost-effective for long runs, as it can achieve high speeds and efficient ink utilization.