Bar Rotary Slittering & Creasing Machine

Products

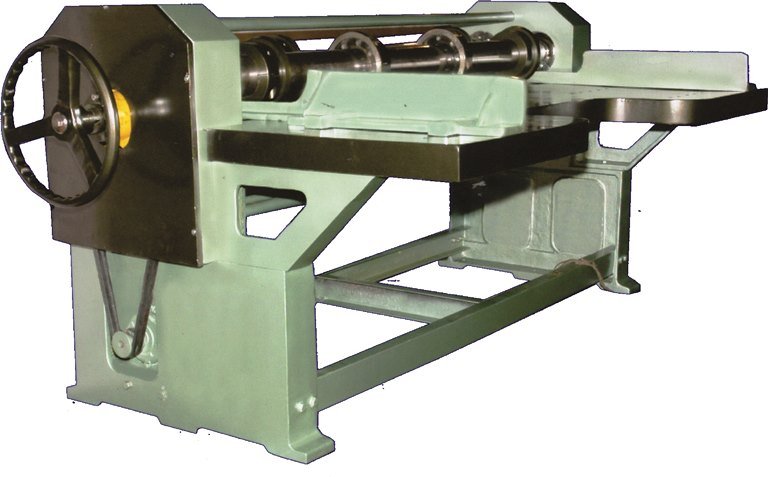

Bar Rotary Slittering & Creasing Machine

A Bar Rotary Slittering & Creasing Machine is a piece of equipment used in various industries, particularly in the packaging and printing sectors. This machine is designed to cut and crease materials such as paper, cardboard, corrugated board, and other flexible substrates with precision and efficiency. It plays a crucial role in the production of packaging materials, boxes, and various printed products. Below are some key features and functions of a typical Bar Rotary Slittering & Creasing Machine:

Slitting: The primary function of this machine is to slit or cut materials into smaller strips or rolls. It can handle a range of materials, and the slitting process is precise, ensuring consistent width and clean cuts.

Creasing: This machine can also create creases or score lines on the material. Creasing is essential for folding the material accurately, which is crucial in creating packages and other products with crisp, clean folds.

High Precision: Bar rotary slittering & creasing machines are known for their high precision. They can make precise cuts and creases, ensuring that the final product has clean edges and folds without any tears or deformities.

Adjustability: These machines typically allow for adjustments in terms of the width and depth of cuts and creases. This flexibility is essential for accommodating different materials and production requirements.

Multiple Blades: Most machines have multiple blades or cutting heads that can be adjusted for different cutting and creasing patterns. This feature allows for versatility in terms of the types of products that can be produced.

Speed and Efficiency: These machines are designed for high-speed production, making them suitable for mass production environments. They can process large rolls or sheets of material quickly and efficiently.

Safety Features: Safety features are incorporated into these machines to prevent accidents and protect the operator. These may include emergency stop buttons, safety guards, and interlocking systems.

Ease of Use: Many modern machines are designed with user-friendly interfaces and controls, making them easy to operate. They may also have automation features to streamline the production process.

Material Handling: Some machines come with features for easy loading and unloading of material rolls, which helps to optimize the workflow and reduce downtime.

Dust and Waste Management: Some models incorporate dust extraction systems to keep the work environment clean and maintain the machine’s performance. They may also have waste disposal systems for collected scraps.

- 65″

- 75″

- 85″

- 95″

- 105″

- 125″

- 300ft.

- 300ft.

- 300ft.

- 300ft.

- 300ft.

- 300ft.

- 3″

- 3″

- 3″

- 3″

- 3″

- 3″

- 1.5 H.P.

- 2 H.P.

- 2 H.P.

- 2.5 H.P.

- 3 H.P.

- 3 H.P.