Eccentric Slotter

Products

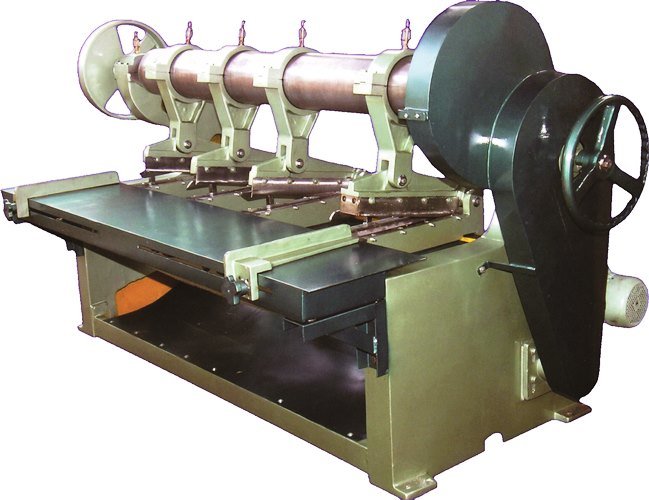

Eccentric Slotter

An eccentric slotter is a machine used in the printing and packaging industry for cutting slots, holes, or creases in corrugated cardboard sheets. It is an essential piece of equipment for manufacturers who produce cardboard boxes, cartons, and packaging materials. The term “eccentric” refers to the design of the machine’s cutting tool, which moves in an eccentric (off-center) manner, allowing it to create various slot or hole patterns with precision. Here are some key features and aspects of an eccentric slotter:

Cutting Capabilities: Eccentric slotters are primarily used for cutting slots, holes, or creases in corrugated cardboard sheets. They can create a variety of slot patterns, including straight slots, T-slots, L-slots, and more, depending on the design of the cutting tool.

Eccentric Motion: The eccentric motion of the cutting tool allows for precise and adjustable control over the slot depth and size. This eccentric movement is typically controlled by a crank or cam mechanism, and it can be adjusted to meet the specific requirements of the packaging design.

High Precision: Eccentric slotters are known for their high precision and accuracy in slot cutting. This is crucial in the packaging industry, where the quality of the slots can impact the structural integrity and appearance of the final product.

Die-Cutting and Creasing: Some eccentric slotters come with additional features that allow for die-cutting and creasing. Die-cutting is the process of cutting cardboard into specific shapes, while creasing involves creating folds or score lines in the material to facilitate easier folding and assembly.

Variable Slot Sizes: These machines often offer adjustable slot width and length settings, making it possible to customize the slots according to the specific requirements of the packaging design.

Speed and Efficiency: Eccentric slotters are designed for high-speed operation, which is essential for meeting the demands of the packaging industry. They can process a large number of sheets in a relatively short amount of time.

Material Compatibility: Eccentric slotters are typically designed to work with corrugated cardboard, which is a common material used in packaging. They can handle different thicknesses of cardboard sheets.

Safety Features: Safety features such as guards and emergency stop buttons are typically integrated into these machines to ensure the safety of operators during operation.

Automation: Some modern eccentric slotters may come with automation features, such as computer-controlled settings and digital displays, to enhance productivity and reduce the margin of error.

Maintenance: Like any industrial machine, eccentric slotters require regular maintenance to ensure they operate efficiently and maintain their cutting precision. This includes lubrication, blade replacement, and general upkeep.

- 65″

- 75″

- 85″

- 95″

- 105″

- 30

- 30

- 30

- 30

- 30

- 14″

- 18″

- 18″

- 21″

- 21″

- 5″

- 5″

- 7″

- 7″

- 8″

- 2 H.P.

- 3 H.P.

- 3 H.P.

- 3 H.P.

- 5 H.p.

- 2.75″

- 3.5″

- 3.5″

- 4″

- 4″